Home > Highlighting JAPAN > Highlighting Japan JUNE 2011 > Out of the Frying Pan Ordinary

Highlighting JAPAN

MONODZUKURI

Out of the Frying Pan Ordinary

Conventional wisdom has it that you can use any frying pan on a household stove low in heating power but you can never cook with it as restaurants do. Yet Nishikimi Chuzo Co. in Mie Prefecture has rewritten that common-sense logic with its Magic Fry Pan. Miho Yanagisawa reports on the company's way of monodzukuri.

Yasuo Nishikimi, president of Nishikimi Chuzo Co.

Credit: TADASHI AIZAWA

Nishikimi Chuzo was originally a small company that manufactured iron mold parts for cars. In 1991 when the bubble economy collapsed, president Yasuo Nishikimi felt the crisis as orders from business partners reduced dramatically.

"We'll go bankrupt if we remain a subcontractor," he reasoned. "We need to make original products."

The following year, Nishikimi realized that if he made cooking utensils with cast iron, which conducts heat twice as fast as iron, food could be made faster and taste better. He took a mock-up of a cast iron steak plate to a restaurant that an acquaintance of his owned. As expected, they told him, "The meat tastes better when cooked on the cast iron plate." The difference between wrought iron and cast iron is in their carbon content. Cast iron is made by melting iron in a furnace of high heat and mixing coal powder. During this process, carbon drops off and leaves minute pores on the surface. Cooking oil seeps into these pores, which enable the plate to fry meat and vegetables thoroughly without charring them. When the acquaintance suggested to Nishikimi that he make a frying pan using cast iron, Nishikimi approached the challenge with confidence.

Challenging Received Wisdom

Having said he would do it, Nishikimi knew that if he were to use cast iron to make a frying pan, which would require at least 4 to 5 mm thickness to maintain durability, it would weigh 3 kg.

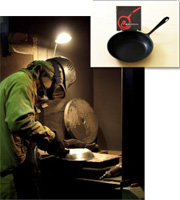

Nishikimi Chuzo Co.'s Magic Fry Pans deliver great tasting food as well as high energy savings—a 30% saving over iron frying pans and 50% over both aluminum and stainless steel, according to tests by the Nagoya Municipal Industrial Research Institute.; inset, ready for delivery

Credit: TADASHI AIZAWA

Revolutionary Pan Wins Top Chef's Approval

After three years of trial and error changing the composition and balance of the mixture of raw materials, Nishikimi succeeded in making a frying pan 2 mm thick, 1,200 g in weight and 26 cm in diameter.

Nishikimi took the finished product to a chef de cuisine at one of the best hotels in Japan and asked him to use it for a week. The chef duly praised the pan's quality, telling Nishikimi that the frying pan worked well even with dishes using foie gras and lobster that demand strict heat adjustments, making them taste better than ever.

Nishikimi's frying pan went commercial. News of the pan's quality spread by word of mouth, and when TV stations and newspapers introduced the product, orders stormed in and overloaded the company's phone lines. But the craze only lasted several months. The reason: "A 1,200-gram pan is still too heavy for a woman to handle."

Back to the Drawing Board

Nishikimi decided that he would strive to make a frying pan 1.5 mm thick.

This mere 0.5 mm difference turned out to be a tough wall to break down. Thinning the iron by 0.5 mm always produced a hole or creases during casting. Days came and went, with Nishikimi trying and failing. But one day, he accidentally mixed twice as much coal into the iron as usual, which turned out to be a lucky break. The additional coal spread throughout the melted iron evenly and created a surface thoroughly cast of small pores, which resolved the issue of holes and creases during forming. Nishikimi had finally overcome the 0.5 mm wall. In 2002, almost ten years after his first mock-up, he produced the ideal, light-but-strong frying pan 1.5 mm thick and weighing 980 g that can make great tasting food.

The Magic Fry Pan made from such challenges continues to sell today. The company expanded on its production line last year and eliminated wait time on delivery. Meanwhile inquiries are increasing from abroad.

| Trade name: | Nishikimi Chuzo Co. |

| Representative: | Yasuo Nishikimi, president |

| Address: | 262 Oaza Sakae, Kisosaki-cho, Kuwana-gun, Mie Pref. |

| Items manufactured: | Vacuum pump parts, frying pans, woks |

| Website: | https://www.nisikimi.co.jp/en |

© 2009 Cabinet Office, Government of Japan