Home > Highlighting JAPAN > Highlighting Japan SEPTEMBER 2012 > Sorting Plastics with Raman Spectroscopy

Highlighting JAPAN

[SERIES] SCIENCE & TECHNOLOGY

Sorting Plastics with Raman Spectroscopy

With so many different types of plastic in use, sorting plastic waste has always been a challenge. Takashi Sasaki reports on a recycling technology that overcomes this major barrier and enables resources to be reused even more effectively.

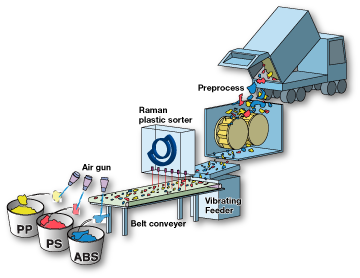

Outline of Saimu's Raman spectroscopy plastic identification system

The system consists of a laser-based Raman plastic sorter, series of air guns, which sort plastics once they have been identified, and other equipment.

Credit: COURTESY OF SAIMU CORPORATION

Although it is possible to identify different types of waste plastic by hand or using near-infrared sensors, issues with cost and accuracy have always prevented such methods from being truly effective. The fact remains that, unless recycling companies can sort large volumes of waste plastic quickly and accurately, they are unable to sell waste plastics to manufacturers as recycled plastic raw materials.

"About five years ago, I went to see Professor Hirofumi Kawazumi from the Faculty of Humanity-Oriented Science and Engineering at Kinki University to talk to him about waste plastic identification technologies. He said to me 'the only commercially viable option would be Raman spectroscopy.' From that point onwards, we started to develop an entirely new identification system, unlike anything the world had seen before."

These are the words of Yasuo Tsuchida, president of Saimu Corporation, which operates a recycling business in Osaka and Fukuoka Prefectures.

Saimu uses Raman spectroscopy to sort waste plastics. This involves shining a light on materials, causing the molecules within to vibrate in their own specific ways and scatter the light in different patterns depending on the materials. The system runs lasers over the plastic fragments in order to detect their Raman spectrum and identify the specific type of plastic. The key feature of the system is its high level of accuracy. The ability to identify a material's molecular structure without actually touching it means that the system can be used on plastic pieces that are still wet from washing and, unlike near-infrared systems that identify plastics with optical absorption, can accurately identify colored plastics. The system is also a hundred times faster than the near-infrared equivalent, taking just three thousandths of a second from laser exposure to identification.

Fully operational since October last year, Saimu's plastic identification system runs crushed fragments of various different plastics along a conveyor belt, at a constant speed of 100 meters per minute. These plastic pieces are identified by a row of fifty laser sensors positioned at intervals of 5 mm, and are then pushed out into the relevant recycling bin by jets of compressed air emitted by air guns at the end of the conveyor belt (see figure).

"The system can comfortably make a profit as long as it produces more than 300 tons of recycled plastic raw materials every month, especially with oil prices riding so high at the moment. We are currently shipping around 500 tons a month at our Kansai Plant in Osaka. That is only possible thanks to Raman spectroscopy," says Tsuchida.

Recycled plastic raw materials are sold on to the likes of home appliance manufacturers, which then transform them into parts for televisions, fridges, washing machines and other new appliances. Whereas recycling waste plastic has been regarded as a corporate social responsibility (CSR) in the past, the development of commercially viable Raman spectroscopy identification technology has the potential to change all that in the future. The main attraction of this technology, apart from helping to protect the environment and use resources more effectively, is that it will enable manufacturers to cut costs. The identification system developed by Saimu can be used for other purposes too, including inspections and identifications in fields requiring a high level of safety such as the food industry and medical industry, as well as plastics. As a result, it is attracting a great deal of attention from companies in a variety of sectors all over the world.

© 2009 Cabinet Office, Government of Japan