Home > Highlighting JAPAN >Highlighting Japan February 2016>Science & Technology

Highlighting JAPAN

Instruments Both Delicate and Strong

Surgery via microscope relies on ultrafine needles smaller than a hundred micrometers in diameter—thinner than a strand of all but the finest human hair. Japan’s Kono Seisakusho Co., Ltd., a trusted provider to medical professionals, produces the world’s smallest surgical needles.

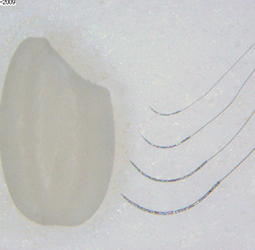

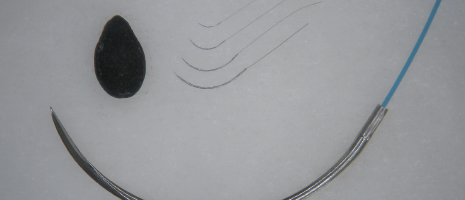

Microsurgery involves operations on narrow blood vessels, nerves, lymph ducts and other delicate tissues. Suturing narrow blood vessels around 500 micrometers wide requires a needle just 100 micrometers in diameter or smaller. But with conventional needles, surgery on tissue elements smaller than five hundred micrometers used to be impossible.

To answer the demands of medical professionals for thinner needles, a Japanese manufacturer rose to the challenge to create the world’s smallest needle—just 30 micrometers in diameter and 800 micrometers long. This was Kono Seisakusho, a manufacturer of needles for timepieces and other implements. The company holds a 60 percent share of the microsurgery needle market in Japan, and almost all surgeries involving tissue structures under seventy micrometers are performed with its products.

These ultrathin needles made previously impossible operations feasible. In suturing the severed fingertips of babies, for example, it allowed the fragile blood vessels and nerves to be sewn together, restoring the finger’s functionality with the most minimal of incisions. Surgery for moyamoya disease, a cerebrovascular condition that involves blocked arteries, also became possible.

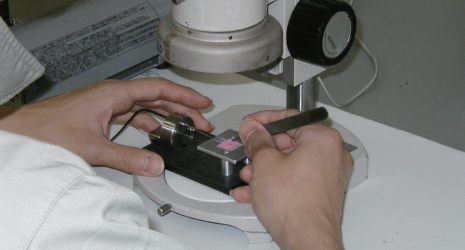

A thirty-micrometer needle, of course, is so thin as to be more a steel thread than a needle. This required engineering a way of giving the tool enough strength to both pierce living tissue and suture it. Moreover, an actual suturing thread must pass through the needle, and the needle’s tip must be pointed. Kono Seisakusho selected a stainless steel that could withstand precision machining and engineered a process in which the jigs, grinders and other machinery involved are operated entirely by hand. The bottom of the needle is actually split in half, creating a channel for the thread to pass through.

Kono Seisakusho’s pride in craftsmanship is evident in the way it relies on more than the handiwork of veteran machinists. “Many of the processes involved in machining superfine surgical needles are done by hand, but we wanted to devise a uniform process so that anyone could achieve a consistent result,” says Junichi Kono, the company’s president and CEO. “We consider the creation of such machinery part of the craftsmanship process.”

Mass production offers one way of keeping costs down, but the company also maintains a separate production line for fully customized products so that it is possible to manufacture a specialized product even if there is only a single patient in need.

Kono Seisakusho also draws on specialized technology that Japan’s small to medium enterprises (SMEs) boast, as well as research results generated by university engineering departments. The company has developed a deep understanding of the needs of the medical field, and combines that knowledge with Japanese technology to create products of real use to medical professionals.

In 2011, Kono Seisakusho obtained a license for the sale of medical devices in China, and is making significant inroads in that market. The company is also exploring new markets in Southeast Asia and Europe. “This is about more than just making and selling Japanese products overseas,” Kono notes. “We want to utilize Japanese technology to create products that these respective medical sectors need.”

As regenerative medicine and transplants gain ground, microsurgery is moving into the realms of gynecology, ophthalmology, otorhinolaryngology and other areas beyond traditional surgery, with ultrathin needles drawing ever more attention. Beyond mere market growth, however, Kono is enthusiastic about using craftsmanship to contribute to real medical needs. “We want to make items that have never been available,” he says. “Our biggest driver is helping patients and doctors.”

© 2009 Cabinet Office, Government of Japan