Home > Highlighting JAPAN > Highlighting Japan March 2018 > Science & Technology

Highlighting JAPAN

Resources from Garbage Using the Power of Microorganisms

A Japanese company has developed a new biorefinery technology that can produce ethanol from everyday burnable garbage.

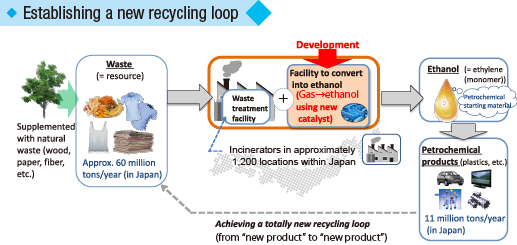

In Japan, most burnable garbage is incinerated. It amounts to about 60 million tons per year and is equal to about 200 trillion kilocalories if it is measured in terms of calorific value. Japan, which has only a small amount of resources, has long focused on the potential use of garbage as a resource and has made efforts in research and development to produce fuel and raw materials from a range of garbage through the private and public sectors. However, issues remain in terms of costs and stable supplies, and the research and development has yet to lead to commercialization. The biorefinery technology developed by SEKISUI CHEMICAL CO., LTD. aims to realize Japan’s long-standing dream.

Biorefinery is the technology of obtaining one substance from another by using the power of microorganisms. SEKISUI CHEMICAL established a method for producing ethanol from garbage by using this technology. It is an innovative technology that enables ethanol to be produced from almost any type of garbage except for unburnable garbage, such as metal.

Koichiro Iwasa, BR Project Head of SEKISUI CHEMICAL, says, “In 2008, we embarked on development efforts to produce industrial materials from garbage. However, this was problematic because the garbage produced by general households undergoes changes in volume and content depending on the season and region. We took ten years to establish our technology.”

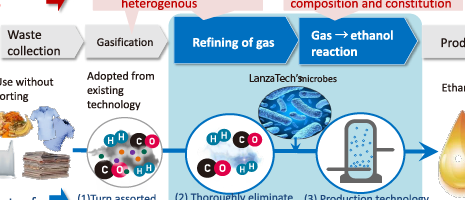

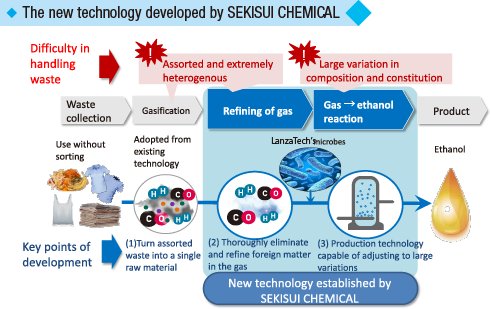

To produce ethanol from garbage, the first thing you have to do is to make garbage burn by itself in a state of low oxygen, resolve it into a molecular level and convert it into gas. Because most of this gas turns into carbon monoxide and hydrogen, ethanol is produced by causing microorganisms that like this environment to metabolize it.

The first issue faced by SEKISUI CHEMICAL was to find microorganisms that were suitable for this process. The company conducted joint development with LanzaTech, an American bio-venture firm, and selected microorganisms that were the most suitable for producing ethanol. The next issue faced by the company was that because the raw materials comprise garbage containing miscellaneous items, it was difficult to keep the activity of the microorganisms constantly stable. By undergoing repeated trial and error, the company tested a method of monitoring the state of gas in real time and removing all components that are not required by the microorganisms by using various filters. The company tested a method of adding nutrition to the microorganisms if they are short of nutrition, and it also tested a method of getting the microorganisms to rest temporarily if the amount of garbage is small. Through this trial and error, the company solved the issues one by one. In addition, by selecting extremely active microorganisms, the company succeeded in producing stable ethanol with extremely high conversion efficiency, even from unseparated garbage collected from ordinary households and factories.

Iwasa says, “If you only place emphasis on efficiency, you can produce microorganisms that meet the objectives with genetic modification technology. But you cannot tell what effect it will have on the environment. We focused on using microorganisms that exist in nature.”

Produced ethanol can easily be converted into ethylene, the material of plastics. Currently, the materials of most chemicals in Japan, including plastics produced, are based on naphtha refined from crude oil. However, there is a possibility that these materials will be replaced by materials derived from garbage someday.

Because this technology does not involve the incineration of garbage, it also has the significant advantage of curbing carbon dioxide emissions. According to trial calculations carried out by SEKISUI CHEMICAL, the technology can reduce CO2 emissions by 22% by stopping incineration compared with CO2 emissions from conventional garbage incinerators. In addition, it is also possible to reduce CO2 emissions by 113% by replacing the production of ethanol derived from crude oil with the technology. The technology will lead to a total reduction of CO2 emissions of 135%.

At a pilot plant that was built at a garbage disposal facility at Yorii Town, Osato County, Saitama Prefecture in 2014, an annual amount of 20 kiloliters of ethanol has already been produced, and there are no qualitative problems. SEKISUI CHEMICAL plans to launch this technology for business jointly with a domestic local government in 2019.

Iwasa says, “We will undertake a wide range of cooperation with local governments both inside and outside Japan, garbage disposal companies, plant manufacturers and chemical manufacturers, in addition to providing our technologies.”

The dream of achieving a resource recycling-oriented society is becoming ever more realistic.

© 2009 Cabinet Office, Government of Japan