INDEX

- English

- 日本語

Discarded clothing (left) and a new T-shirt (right) made using the polyester recycled from it - English

- 日本語

The “Go! DeLorean” event in 2015

August 2020

New Technology for Recycling Used Clothes

All around the world, large quantities of clothes are discarded every year. However, efforts to recycle these clothes into resources have advanced poorly. A Japanese venture company has developed proprietary recycling technology for discarded clothes, and is expanding its operations by successfully producing bioethanol that can be used to fuel automobiles and recycled polyester that can be used for making clothes.

In Japan, nearly 1.7 million tons of fiber products are discarded annually. Reportedly, most of them are clothes. Few of these clothes are recycled into anything else, such as raw materials for felt. Most of the discarded fiber products are incinerated or put into landfills. The situation is similar in Western countries. It is estimated that more than 90 million tons of waste is generated annually by the global apparel industry. The figure is nearly twice as large as the total amount of waste discarded annually in Japan, about 43 million tons according to the Ministry of the Environment in March 2020. With its proprietary technology and original ideas, JEPLAN is committed to the recycling of the large amount of fiber products that would otherwise be destined to be incinerated or put into a landfill.

When the venture company started in 2007, it was very small with two staff members only. They started by pursuing technology to create bioethanol from collected used clothes. Bioethanol is plant-derived ethyl alcohol that is normally made from sugar cane, corn, waste wood and other biomass resources (biological resources). Mixed with gasoline, bioethanol is mainly used as fuel for automobiles. JEPLAN conducted research in collaboration with Osaka University, and by glycosylating and fermenting the cotton fibers of used clothes, successfully recycled them into a fuel which can be used as an alternative to heavy oil. Furthermore, in 2017, JEPLAN developed a technology for recycling the polyester fibers in used clothes. By applying a chemical method for recycling, JEPLAN succeeded in recycling used polyester in a way that enabled it to be qualitatively equivalent to a brand-new product.

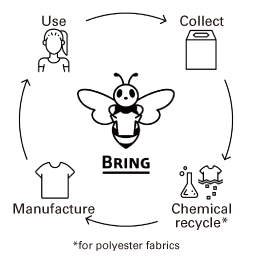

Currently, JEPLAN is operating the project “BRING,” a recycling business. This project invited clothing distributors and other apparel companies to participate. Thanks to their cooperation, JEPLAN set up about 2,000 collection points around the country collecting used clothes and other cast-off fiber products. The polyester in the clothes collected from consumers is recycled and then used to manufacture products such as the T-shirts that are sold under the BRING brand, and to supply apparel manufacturers with the recycled polyester. In the past, there was nothing that could be done with used clothes other than reusing them as clothes. However, the introduction of this recycling technology makes it possible for used clothes to be recycled into new clothes and be worn again and again. “Used clothes can be transformed into new clothes.” That means, used clothes have been transformed into new recycling resources.

According to Okita Aiko, a public relations representative of JEPLAN, the BRING brand takes its name from consumers’ bringing goods for recycling.

“A sound material-cycle society cannot be achieved by a single company alone. Cooperation from many distributors and manufacturers is indispensable. Gaining the involvement of consumers is the key to realizing a sound material-cycle society,” says Okita.

The project BRING organizes many different events with the goal of engaging consumers and increasing their interest in recycling. “Go! DeLorean” was held in 2015 to accomplish this. The DeLorean is the car that was used to make the time machine in the Back to the Future movies, that is fueled by raw garbage and runs around space and time. On October 21, 2015, to imitate the movies, it was decided to run the car on bioethanol obtained from the clothes collected from event participants beforehand. The idea for the event came from Iwamoto Michihiko, one of the cofounders of JEPLAN and the current chairperson of the company. He watched the movie as a student and had been very impressed by it, so he cherished the idea of running a DeLorean on recycled biofuel since the company started up.

Go! DeLorean became a reality partly because of cooperation from film distributors. The event was covered by the media both domestically and internationally, drew interest from many people, and in the three-month period running up to the event collected more than 20 tons of clothes for recycling, which is the amount of clothes normally collected by the company in one year.

JEPLAN pursues overseas expansion of BRING through licensing, as well as by increasing the number of clothes collection points in Japan. For example, JEPLAN tested the project BRING operations in Lyon, the city at the heart of the fiber industry in France, in an effort to facilitate the project in collaboration with a local fiber organization.

“Used clothes can be transformed into new clothes.” This new circle of clothes recycling is expected to spread all over the world from Japan.