INDEX

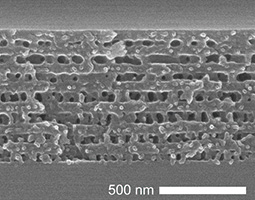

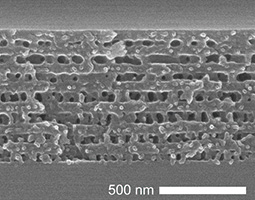

Cross-section of the multilayered polymer structure that generates the structural colors, made using OM technology

CD rainbow colors, which are examples of structural color.

October 2020

High-Precision, Full-Color Printing without Ink

A research team at Kyoto University has developed a new technology for recreating ukiyo-e prints and other multicolored artworks through high-precision printing without the need for ink. The group is now working to develop the technology for practical use.

A compact disc (CD) sometimes appears to have a rainbow-colored surface, even though it is not actually colored itself. This is because the light hits the minute irregularities that have been placed on the CD’s surface in a well-ordered fashion for the sake of recording data, and the wavelengths of the reflected light “interfere”* with each other so that they look like light exhibiting various colors—red, blue and so forth. Since the colors come from the surface structure patterns, they are called “structural colors.” Representative examples of structural colors are the glossy green and red of jewel beetle bodies and the eye patterns on peacock feathers. In the case of the jewel beetles, the surface of their bodies consists of multiple overlapping films that create the appearance of a colored surface as the reflected light from the different films interferes.

The research group of Professor Easan Sivaniah and Program-Specific Assistant Professor Ito Masateru at Kyoto University has developed new technology that can artificially create such structural colors and has realized multicolor ultra-high-precision printing that does not use ink.

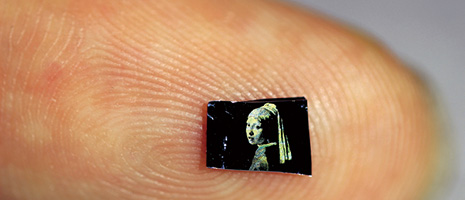

One full-color product that the research group made using the new technology is The Great Wave off Kanagawa by Katsushika Hokusai, a world-famous ukiyo-e piece. The original has a bold composition that depicts three small boats on a raging sea expressed in white and blue as well as Mt. Fuji on a block measuring 25.7 cm x 37.9 cm, but the research group was able to recreate this in structural colors without ink on a minimal scale only 1 mm wide.

To create the structural colors, it is necessary to artificially create patterns or multiple layers on a material surface to reflect the light in various colors, just like CDs and jewel beetles. It was for this purpose that the research group developed technology based on the phenomenon of “crazing.” Crazing refers to the making of a structure consisting of fibers on a nanometer scale (one-millionth of a millimeter) called “fibrils” by beginning the cracking process inside plastic and other polymers through the application of pressure. An everyday example of crazing is how a clear plastic folder turns white at the crease if you bend it. The white color does not come about because the creased plastic actually turns white, but because the fibrils created by the crazing change the structure of the creased part so that light is reflected to look white.

The technology, called “OM” (organized microfibrillation), developed by the research group, causes crazing by radiating LED light on polymers to form preferred cracking areas before exposing the polymers to a solvent. This process creates multilayered fibrils that generate structural colors, just like the surface of a jewel beetle’s body. Using this technology will make it possible to create fibril structures that reflect red, blue, or light in other colors in specific locations.

Regular printing creates images by aggregating small dots. Smaller dots and more dots make it possible to achieve higher-precision printing. The pieces recreated by the research group this time are also images that consist of aggregations of dots that generate structural colors.

Ito of the research group explains, “In order to make higher-precision images, we struggled to make the dots smaller and smaller. In the end, we achieved an image resolution of 14,000 dpi [14,000 dots per inch]. Structural colors give off color through a delicate control of light, so it can realize light and color effects that can’t be done with ink, such as color changes depending on the angle you’re looking from. Also, the colors won’t fade with time since we’re not using the chemical substance that is ink, and it can be said to be environmentally friendly since we’re keeping down the waste products that come from ink production and printing.”

At present, the research group is working to develop the technology for practical use by increasing the capabilities of the device that radiates the light that causes the crazing. The device is currently unable to radiate anything bigger than 10 cm2, but if that can be expanded to several square meters, then it becomes possible to do large-scale high-precision printing. According to Ito, “We’re aiming for the OM technology to have practical applications in the security printing field. We think that it can be used to prevent forgery of gift certificates and identity documents since the fibrils, which are cracks inside polymers, are difficult to copy.”

* Interference of light is a phenomenon where multiple light wavelengths overlap to make the light stronger and weaker.