Home > Highlighting JAPAN > Highlighting Japan September 2016 > Japan’s Fight Against Global Warming

Highlighting JAPAN

Cool Shirt!

The annual Cool Biz campaign that kicked off in 2005 has accelerated the development of highly functional fibers that can make the hot Japanese summer feel cooler and more comfortable.

In the past, it was normal for Japanese business persons to wear suits and neckties at work throughout the year. This attire made the hot and humid Japanese summer conditions difficult to endure.

The Cool Biz campaign promoted by the Ministry of the Environment as a part of its measures to combat global warming was a game changer. The aim of this campaign is to curb electricity consumption and reduce CO2 emissions by raising the air-conditioning temperature in the office and at home. Cool Biz is a lifestyle that enables people to more comfortably enjoy time spent indoors with the air conditioning set at 28°C.

Many companies adopted the Cool Biz idea and began to encourage their employees to wear lighter clothing immediately after the campaign was launched in 2005. Today it is common for business persons to go without a jacket or necktie in the summer. Today Cool Biz is a synonym for light business attire in the summer.

The spread of Cool Biz style helped to speed up the development of highly functional fibers used to make more comfortable clothes.

“Highly functional fibers were created by adding special functions to fibers such as polyester,” says Akihiro Omatsuzawa of the Japan Chemical Fibers Association. “Japan continues to lead the field in the development of highly functional fibers in the global market. It is the only country in the world where new highly functional fibers continue to be developed.”

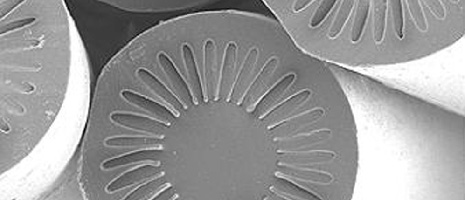

There are four main types of highly functional fibers used to make clothes for Cool Biz attire. The first type is a material that can absorb a lot of sweat and dry the body quickly. It employs a mechanism that increases the area in which the fiber comes in contact with the sweat by increasing the fiber’s surface area to facilitate the smoother absorption of more sweat. To enlarge the fiber’s surface area, they develop materials that combine fibers by making them fine or changing the fiber shape to allow for the smoother absorption of sweat. The enlarged fiber surface area also helps the absorbed sweat to spread and evaporate more easily, which in turn makes the material dry more quickly.

The second type is a material that feels cold when it is touched. It is highly hydrophilic and allows for heat to pass through it easily, making it possible to quickly absorb heat from the skin. As a result, it feels cold when it is touched. There are some products which feature a dual-structured fiber with polyester on the inside and a highly hydrophilic and thermal conductive special material on the outside.

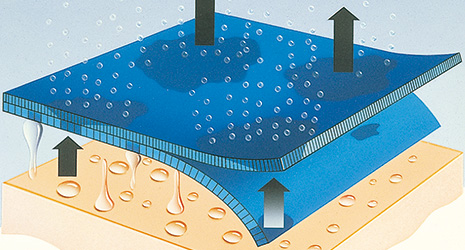

The third type is a material that can control and adjust air-permeability. It is designed to facilitate and enhance air-permeability by stretching the fiber and opening the stitches when people sweat and their clothes get more humid. It also controls air-permeability by closing the stitches when the clothes dry. This mechanism allows for the automatic adjustment of the humidity and temperature of clothes, providing an effective means for staying comfortable.

The fourth type is a heat-isolating and -insulating material. It blocks sunlight and heat, and prevents the temperature from rising inside the clothes. Another type of material that has been developed is an ultraviolet ray-isolating and -insulating material. It works in a similar way to absorb and diffusely reflect ultraviolet rays.

“Highly functional fibers are becoming more workable and effective year by year, and also more comfortable,” says Omatsuzawa. “Numerous fiber manufacturers have been working hard in recent years to add more advanced functions, and have been conducting research and development on adding multiple functions to one particular fiber product.”

In addition to materials for Cool Biz attire, the use of highly functional fibers has also spread to leisure, such as sports clothing. Japanese highly functional fibers are used for the products of many globally recognized sports brands. In addition, there are also highly functional fibers that can retain warmth. These are commercialized for Warm Biz, which aims to make people feel comfortable indoors in the winter time with the heat set at 20°C. Manufacturers have developed materials that can convert absorbed solar energy into thermal energy, and materials that generate heat by absorbing water.

One of the reasons that Japan has taken the lead in the development of highly functional fibers is that the nation not only possesses manufacturing technologies for fiber materials, but also excellent fabric processing and dyeing processing technologies. Evidence of this can be seen in the fiber-producing areas in the prefectures of Fukui, Ishikawa, and Toyama in the Hokuriku region, where the fiber industry has thrived since the Edo period (1603–1867). Leading Japanese companies with high-level technologies for chemical fiber processing are concentrated in the Hokuriku region. Along with the processing of highly functional fibers, many small and medium-sized enterprises operating in this region are actively working to apply the latest uses for the next generation. There is a fabric manufacturer in Fukui Prefecture helping with the development of the Heart Recovery Patch, on which the TV drama “Shitamachi Rocket,” a big hit last autumn, was modeled.

“Manufacturing products made of highly functional fibers is no easy task,” says Omatsuzawa. “They are the result of combining the latest technologies of chemical fiber manufacturers with the craftsmanship that has developed in fiber-producing areas over the centuries.”

© 2009 Cabinet Office, Government of Japan