Home > Highlighting JAPAN > Highlighting Japan November 2018 > Science & Technology

Highlighting JAPAN

Sensitive Robotic Arms Hold a Better Future in Their Grasp

A newly invented pair of robotic arms and hands boasts a grip sensitive enough to pick up something as light and delicate as a potato chip. It also incorporates haptic technology that transmits the sensation of actually holding and manipulating the object being held, offering exciting possibilities for avatar robots and prosthetics.

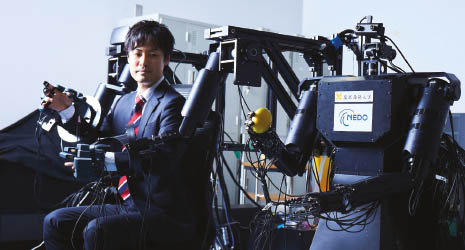

The dual-arm robot assistant professor Takahiro Nozaki and his team at Keio University’s Department of System Design Engineering have built—dubbed General Purpose Arm (GP-Arm)—can pick up potato chips with its fingertips and hold water balloons without bursting them. While traditional robots struggle to perform such actions, GP-Arm succeeds handily because it can vary its grip pressure just like a human can.

GP-Arm consists of a human-operated master unit and a slave unit with robotic arms. When the hands grip an object, they transmit the tactile sensation to the operator’s fingertips, allowing the latter to adjust the robot’s grip appropriately. The slave unit has a camera that feeds images to a head-mounted display on the master unit, and when the operator applies pressure the muscle contraction measurement system attached to his or her foot picks up this feedback, and allows the operator to move the robot forward and backward. The system allows people to explore remote locations as though they were actually there and touching and manipulating objects directly.

The core technology behind the mechanism that transmits tactile sensations is known as acceleration-based bilateral control, an advanced haptic technique that Professor Kouhei Ohnishi of Keio University’s Haptics Research Center introduced to the world in 2002. The technique involves turning the reactive force when the robotic arm handles an object into a digital signal in real time, which is then translated into the torque of a motor each time force is applied.

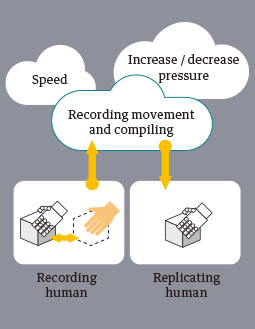

Since this data is relayed to the operator instantaneously, it produces the realistic sensation of touching an object. The haptic data from the operator’s grip adjustments is also recorded and modeled, so robots without operators can perform the same actions.

“Of the five senses, touch is the most difficult to reproduce with machines,” says Nozaki, describing his research into real haptics. “Haptic technology used to rely on phenomena such as vibrations to transmit pseudo-sensations of touch, like you’d find on a video game controller. Although that creates the illusion of holding something, it’s not enough when it comes actually picking up an object.”

The GP-Arm’s range of potential applications is extensive, including medical care, nursing and manufacturing, and Nozaki and his team are carrying out collaborative research and trials with various companies. Some machines already incorporate this system, including one that sorts mandarin oranges according to size and hardness, and another that handles many different kinds of screws. Magnifying or reducing the force the operator exerts will lead to further applications, making it possible to lift heavy objects and perform microsurgery.

A prosthetic hand that can feel has been developed using these techniques. Mounting the controls under the armpit was considered, but practical testing revealed that operating the prosthesis with the toes was easier—the prosthetic hand moves in sync, and feeds back the sensation of grasping objects to the toes. This type of prosthesis is cheaper than myoelectric hands that respond to brain signals, and requires no special training. Participants in the experiment said the best thing was being able to feel the objects they were holding.

“In Japan, with its low birthrate and aging population, the shrinking workforce is becoming a major issue,” says Nozaki. Being able to vary the force that a robot exerts is particularly important in fields concerned with people, he explains, such as medical care and nursing. Nozaki believes this technology will play an essential role as additional manpower for manufacturers, or as robots that help seniors go about their daily lives.

Nozaki announced in September 2018 that he and his team are joining the AVATAR X Program, launched by ANA Holdings and the Japan Aerospace Exploration Agency, to develop their haptic technology for use in space. The possibilities of realistic interaction never experienced by humankind will extend all the way into the cosmos.

© 2009 Cabinet Office, Government of Japan