Home > Highlighting JAPAN > Highlighting Japan May 2019 > Science & Technology

Highlighting JAPAN

“Sophia” Wisdom for Reducing Electric Power Loss

A new power semiconductor device using gallium oxide to achieve less electric power loss has been developed. The innovation is expected to greatly contribute to the energy-saving and miniaturization of electronic products.

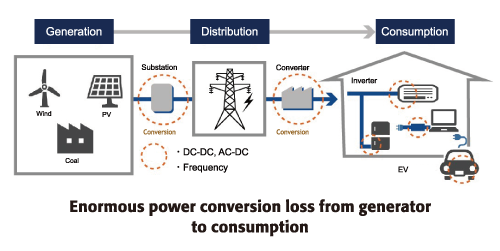

Electronic products, large and small, such as AC adapters, home electric appliances and electric cars, use power semiconductor devices. Power devices are used for power conversion: inverters change direct current into alternating current and converters change alternating current into direct current. Electronic products are becoming increasingly energy-savings oriented, and there is growing demand for high-quality and low-cost power devices. There is cutthroat competition for the development of such power devices among companies both at home and abroad.

One of the major problems for power device developers is how to reduce electric power loss. For current power devices, electric power is lost in the conversion between direct current and alternating current. Electrical goods, such as AC adaptors or computers, generate heat when in use. This is because some electricity is lost in the form of waste heat. It is estimated that 10% of the total electricity generated in Japan is lost in power conversion. That is, 10% of Japan’s electricity ends up as waste. However, reducing electric power loss has been considered a difficult problem to solve because of the material properties of silicon, the material most commonly used in semiconductors.

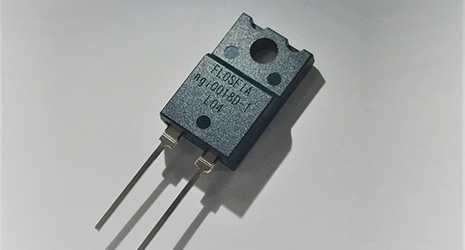

FLOSFIA Inc., headquartered in Kyoto, founded in 2011, succeeded in developing a low-power-loss and low-cost power device by using α-Ga2O3 (Corundum Structured Gallium Oxide), a material first created at Kyoto University in 2008.

Gallium oxide has attracted attention as a semiconductor substance that, like silicon carbide and gallium nitride, could replace silicon. The difficulty of producing high-quality, low-cost gallium oxide using conventional semiconductor manufacturing methods, however, made it extremely difficult to make profitable power devices.

Toshimi Hitora, president of FLOSFIA, says, “Engineers working for major companies said that it was impossible to commercialize gallium oxide power devices. Major corporations would not do it, so it was a great opportunity for a venture company like us to be the first.”

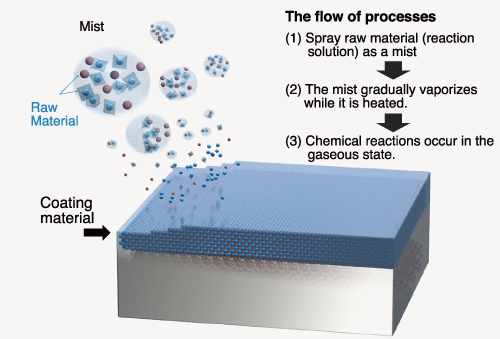

The core technology for making α-Ga2O3 is the MISTDRY method. The method entails heating and vaporizing the raw materials into a mist, generating chemical reactions in their gaseous state to form a thin film. Because this method does not need an expensive vacuum device, unlike in conventional semiconductor manufacturing, production costs can be reduced to a tenth of those for silicon carbide-made power devices. Moreover, the method does not use environment-polluting substances like cyanide, so it has the additional benefit of being environmentally friendly.

FLOSFIA created an α-Ga2O3 power device in 2016 that reduced electric power loss significantly over silicon-made power devices manufactured by other companies. FLOSFIA expects that their power devices will be soon installed in AC adaptors and home electronics, as well as in industrial devices, such as robots and X-ray equipment, from 2020.

FLOSFIA’s technology has attracted the attention of major companies. In 2018, FLOSFIA announced that it would start jointly developing low-power-loss, low-cost, miniaturized, light-weight power devices for hybrid and electric cars with automobile parts manufacturers, aiming to bring them to market by 2025. The use of power devices with reduced electric power loss will extend the mileage and reduce vehicle body weight.

Hitora says, “I believe that α-Ga2O3 power devices have the potential to have a huge impact on industry. Our goal is to produce devices that meet public demand and contribute to creating a new industry.”

FLOSFIA’s name represents the company’s goal to put the polish on the “flow” of “sophia” wisdom and to flow it back into society, thereby contributing to the progress of humankind. The company is just taking the first steps now.

© 2009 Cabinet Office, Government of Japan