March 2023

Concrete that Repairs Itself

Basilisk HA (Basilisk Self-Healing Agent)

Crack repair demonstration at New Chitose Airport, Hokkaido

A self-healed (right) crack in a block of concrete

A Japanese company has commercialized a type of concrete that repairs itself, the same way that a living organism heals a wound. Its use as a building material is expected to result in lower levels of carbon dioxide emissions.

Concrete has a high compressive strength but a low tensile strength, a weakness that makes it vulnerable to cracking due to drying and shrinkage. This weakness is mitigated by reinforcing concrete with reinforcement bars. However, cracking in the concrete itself allows air and water to penetrate, causing the reinforcing steel bar to rust. As a result, the concrete structure fractures and eventually collapses.

Basilisk HA (Basilisk Self-Healing Agent) is a self-healing concrete jointly developed by Aizawa Concrete Corporation headquartered in Tomakomai City, Hokkaido, and Delft University of Technology in the Netherlands to overcome this shortcoming of concrete.

“To most people, the notion of a type of concrete that repairs cracks by itself the same way that a living organism heals a wound may sound like science fiction,” says Aizawa Yoshihiro, President of Aizawa Concrete Corporation. “In fact, the history of technological development of using living organisms to give concrete a self-healing function is surprisingly old. Our own Aizawa Technical Research Institute started an approach using organisms such as Bacillus natto* more than seven years ago, and it was in the course of this research that we came across bacteria with excellent alkali tolerance that the research group at Delft University of Technology in the Netherlands had succeeded in cultivating.”

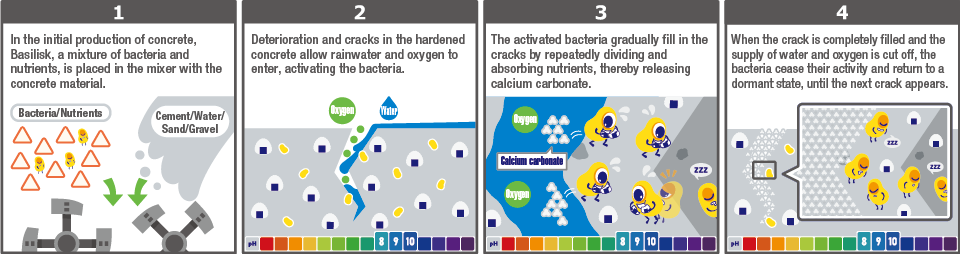

The technology developed by Delft University of Technology can be summarized as follows. First, granular capsules comprised of alkali-tolerant bacteria and polylactic acid are created, which serves as a nutrient source for the bacteria. They are then mixed into the concrete. Water and alkali components in the concrete cause the polylactic acid to gradually degrade and convert into calcium lactate. The bacteria cannot be activated in the highly alkaline environment of concrete (pH 12–13), so become dormant. However, if the pH of the concrete falls to a level of between 8 and 10 as a result of rainwater and oxygen penetration through a crack in the concrete, the bacteria fed by the calcium lactate become active again and multiply. As the multiplying bacteria absorb the calcium lactate, they release calcium carbonate (limestone), which fills the gaps between the cracks, repairing the concrete. The activation of the bacteria releases carbon dioxide (CO2) as well as calcium carbonate. Calcium carbonate is also released when this CO2 combines with calcium hydroxide dissolved from the concrete. The calcium carbonate released by this chemical reaction then steadily fills the gaps between the cracks. Once the gaps between the cracks are completely filled, the alkalinity in the concrete increases again, and the bacteria return to a dormant state.

However, the practical application of this technology proved challenging. President Aizawa recalls, “The most difficult aspect of developing self-healing concrete was figuring out how to achieve mass production, given that engineering and building projects utilize enormous quantities of concrete. The bacteria studied by the researchers at Delft University of Technology were very promising. But because the method involved encapsulating the bacteria with polylactic acid before mixing into concrete, production efficiency and cost considerations made it unsuitable for mass production.”

Joint development of the technology began in 2017, and its ultimate success was thanks to Aizawa Concrete Corporation’s specialized mixing technology. Over a period of some two and a half years, the Company devised an ultra-high-speed mixing method under decompression that encapsulates extremely small bacteria in polylactic acid, producing a large amount of powder**. This innovation led to the commercialization and mass production of the world’s first self-healing concrete. In November 2020, the Company began producing 10 tons of self-healing concrete per day, equivalent to around 700,000 square meters per year.

“The findings of our research show that bacteria can survive in concrete for around 200 years. The self-healing function of concrete will be maintained throughout that time. This means that its lifespan is extended dramatically when compared to the lifespan of standard reinforced concrete, which is around 50 to 60 years. What’s more, repairs to cracking and deterioration will require less manpower and be less costly than is the case with traditional concrete. And it will have a big impact in the drive to realize a decarbonized society,” says President Aizawa.

Social infrastructure that makes extensive use of reinforced concrete such as roads and ports is designed to last 50 years. If this period were to be doubled by using self-healing concrete, both the burden on public funds and future CO2 emissions from the manufacturing of cement, the raw material for concrete, would be cut in half. At present, each ton of cement produced emits approximately 0.8 tons of CO2. In Japan, the manufacturing of cement releases around 34 million tons of CO2 into the atmosphere each year, accounting for 5 to 7 percent of the country’s total industry emissions. Hence, reducing emissions has been a longstanding challenge. Self-healing concrete will help resolve this challenge when viewed in the long term.

In July 2022, the self-healing concrete Basilisk HA was registered in the New Technology Information System (NETIS), a database created by the Ministry of Land, Infrastructure, Transport and Tourism to promote the application of new technologies. In January 2023, the product received the Excellence Prize in the 9th Monodzukuri Nippon Grand Awards. In Japan, where social infrastructure facilities are deteriorating as they approach the end of their lifespan, self-healing concrete is likely to have a very important role to play.

* A strain of Bacillus subtilis used in the commercial production of the food natto, fermented soybeans.

** A solid composed of a large number of particles