Home > Highlighting JAPAN > Highlighting Japan March 2018 > Technologies for Disaster Mitigation

Highlighting JAPAN

Seismic Isolation Made Simple

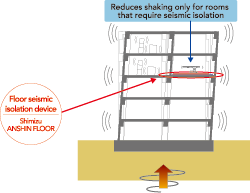

A new partial seismic isolation technology enables low-cost and highly effective construction of earthquake-resilient floors where a building most needs them.

Shimizu Corporation focuses its research on seismic isolation structure technology to protect buildings from major earthquakes. Seismic isolation structures are divided into two types: seismic isolation for an entire building and partial seismic isolation only for the necessary parts. Because low costs and short delivery periods are required for its introduction to existing buildings, demand has grown for partial seismic isolation when seismic isolation cannot be applied to entire buildings.

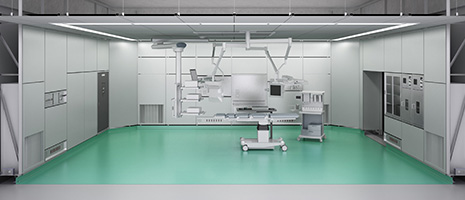

Through various investigations following the Great East Japan Earthquake, Shimizu Corporation heard from many medical workers that they faced problems continuing operations during strong vibrations despite sufficient the earthquake-resistant performance of buildings. Medical workers also said that if seismic isolation had been applied to operating rooms when the earthquake occurred, operating tables would not have been shaken, safety could have been easily secured for patients, medical equipment could have been prevented from falling and medical operations could have resumed quickly following the earthquake.

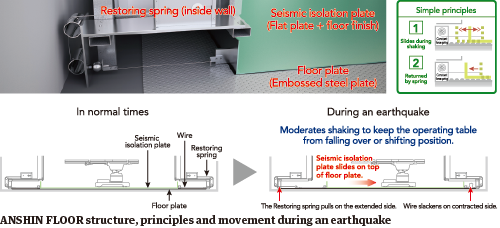

In response, Shimizu Corporation developed a partial seismic isolation floor system (Shimizu ANSHIN FLOOR) for operating rooms that has a simple structure of just two thin steel plates on the floor. This system facilitates high-level seismic isolation effects for the structure of the upper seismic isolation plate with a flat plate (sliding steel plate) sliding on a floor plate (embossed steel plate).

Akira Fukukita, General Manager of the Center for Safety and Reliability Engineering at the Institute of Technology, says, “Shimizu ANSHIN FLOOR has two characteristics. First, because it is thin, it can be applied to both new and refurbished buildings. Second, springs are used so that operating room floors [fitted with seismic isolation plates] will return to their original positions after the earthquake has ceased.”

To find a suitable steel plate for use as a floor material that slides well, Shimizu Corporation conducted many tests to confirm whether the strength and durability could be maintained with thinner plates. They discovered that the thin steel plates manufactured by Nippon Steel & Sumitomo Metal Corporation used for white household appliances, such as refrigerators, satisfied the seismic isolation performance they sought. Because Shimizu ANSHIN FLOOR uses a thin steel plate of 1.6 millimeters for the floor plate and seismic isolation plate, the installation as a whole is about 5 millimeters thick, including a floor sheet for the finish.

Next, Shimizu Corporation moved on to select the springs to connect the seismic isolation plate with the building floor to facilitate the sliding floor returning to its original position. Fukukita says, “We chose a special spring called a constant load spring. Normal springs generate restoring force proportional to the amount of pulling, but constant load springs produce a certain level of restoring force irrespective of the amount of pulling. The seismic isolation plate starts to move when an earthquake with a seismic intensity of more than 5 occurs. We wanted it to return to its original position when the earthquake ceased. The key to our development was the level to which we should set the strength of the springs.”

General operating rooms have dual wall structures. There is an operating room in the inside wall and a 70 to 80 centimeter-wide space that stores a power supply device and air-conditioning equipment. By storing the springs there and hanging the inside wall from the building frame, the team created space between the building floor and the walls, which allowed the operating room floor to slide. As a result, the operating room looked normal. The team successfully applied a seismic isolation structure to the operating room so that its floor would slide in the event of a major earthquake.

Fukukita says, “It took four years for us to develop this technology. Maintenance is hardly necessary after the completion of the structures. We conducted many tests based on more than ten types of earthquake waves that occurred in the past, such as inland earthquakes and subduction-zone earthquakes, and confirmed the seismic isolation effect for all earthquake waves.”

With Shimizu ANSHIN FLOOR, seismic isolation can be achieved in the required areas of renovated buildings as well as in new buildings. It can protect valuable devices and equipment from earthquakes. Recently, a number of companies have decided to introduce the Shimizu ANSHIN FLOOR to their server rooms, as applications for the technology begin to expand beyond operating rooms.

© 2009 Cabinet Office, Government of Japan